End users are increasingly demanding the product content they are presented with when it comes to their omni-channel experience, and this both online and offline. This forces companies to forever raise the bar for collaboration, communication and data exchange between departments. An ERP (Enterprise Resource Planning) is not always the solution here. However, a PIM (Product Information Management) can provide a better answer to this. But what exactly is the difference between ERP and PIM? YellowGround found out for you. Read more in the blog.

ERP vs PIM – what are the differences

What is ERP?

ERP, or Enterprise Resource Planning, is software used by organisations to manage day-to-day business processes. Think orders, logistics flows and distribution, HR, accounting/finance, supply chain operations stock, pricing, etc. An ERP system uses a common set of data definitions operating on a single database, which functions on an integrated software platform.

What is PIM?

PIM, or Product Information Management, stands for managing all product-related information. Marketing and sales need accurate, appropriate, consistent and complete product information, which is consolidated in a PIM system. From product specifications, product lifecycle information, technical specifications, digital assets, rich media, product metadata and information gathered from any internal or external source or department related to the organisation. From the PIM system, this information is then disseminated to every point of contact with the customer. The PIM platform enables companies to become more consistent, efficient and compliant through a seamless flow of reliable product information. From production through the supply chain to the market and finally to the customer!

ERP or PIM?

In the past, companies often only had an ERP system, as a core part of the business, which was enough back then. Over time, this ERP system was often extended further, the more extensive the organisation became. Logistics, price management, warehouse management… all transactional matters were facilitated in the ERP system. In a traditional brick-and-mortar sales channel, there was often no need for extensive product data management. With the battle of digitisation and the multichannel experience that customers are used to, product data needs to be offered to the customer through more channels. It is therefore important to start managing product data centrally, so that this product data is and remains consistent with respect to all touchpoints with which your customer comes into contact with your product data. Then we no longer look at ERP but at a PIM system.

Do we put the information in ERP or in PIM? That is often a question that comes up only when ERP can no longer keep up. ERP is not made to manage product data. If you want to manage product data in ERP, you have to customise the ERP: an expensive and time-consuming solution that often also comes with the necessary technical limitations of your ERP package. This is not a future-proof solution; the software will not evolve along with market demands. Each time, you have to have an update developed that fits your needs and the needs of the market. Even with something as small as adding an extra attribute to your products, you have to bear a developer cost. At some point, you have customised your ERP system broken. A PIM system is built to manage product data. So you use the tool’s standard features. Does market demand change? Then your PIM system will offer the solution!

What’s in a PIM and not in an ERP?

So, as we have already said, PIM is really specifically about managing product data. What is integrated in a PIM system and not in an ERP system:

- Asset management: automatically creating technical data sheets and automatically updating technical data sheets. Think of photos, datasheets, nutriscores, installation guides… For example: within ERP, you cannot add an installation guide. These are then usually on a shared folder, where you have to manually look them up and download them. A customer now expects to be able to download the installation guide directly from the website accompanying the product. PIM makes this possible.

- Taxonomies and data standards: Every industry has to follow the market around data standards, such as ETIM 8, for example. These change continuously, your product data model needs to be kept up-to-date continuously, which is much easier within PIM. Within PIM you can manage taxonomies separately. VB: industry is still mainly on ETIM 7, even though standard ETIM 8 also still exists and ETIM 9 is just around the corner.

- Attribute management. Within a PIM, you can easily modify, add or remove attributes according to your customers’ demands. Say you have lots of products in 35 different shades of blue: from royal blue to azure. You want customers to be able to easily search on the colour ‘blue’, so you’d like to add the new attribute “basic colour” to your products. If you only have an ERP system, this is a complex implementation, you need to involve IT and you have a long lead time before it will be available within your ERP system. Within PIM, this is simple and quick to adapt or add and involves absolutely no development.

- Data quality metrics for different channels. This is not available in ERP system. Within PIM system, you can have different data quality rules across product divisions and sales channels. This can be very useful for sales through marketplaces. Bol.com, for example, has different requirements to be allowed to sell on its platform. For instance, product images must meet certain quality conditions and certain product attributes must be completed. These may be different from the quality conditions of your own e-commerce. Within PIM system you can easily add these rules, within ERP this is impossible without the necessary customisation. Apply this to the example from before: adding the attribute ‘basic colour’. Suppose this is a request from the marketplace: an extra attribute must be added to the product data to be allowed to sell. Within PIM, you can easily adjust this within your dashboard to see how many products are missing this attribute. Within an ERP you will have to export all data to an external report, this is much more manual work, so you are much more likely to make mistakes.

- Data governance. If you need to work with different people on the product data, this is easier to set up in a PIM system than an ERP system. You can work and coordinate with different teams on data in parallel or sequentially. ERP is not aimed at setting up a workflow, with different people taking care of different pieces. A PIM system also provides guidance for your specific tasks. For instance, the translator will see on his screen only the data to be translated on the left and the place to translate on the right. He will not see all the other information, which is not relevant to him. Suppose you are responsible for 50 ‘safety’ attributes of a technical product, he shouldn’t go looking for your attributes among 1000 attributes. In a PIM system, depending on your role and the process (the workflow), you will have a specific screen dedicated to your tasks.

- Golden record creation & different sources. When you start bringing together different sources of information and from there create one single source of truth for your data. With a PIM system, you can bring different product data sources together, giving you traceability to the different sources. This can be important for example for allergens in food products or safety information in technical products. You want to know where the information comes from. If you want to know more about golden record principles, be sure to read the blog.

- Attribute metadata management. This is specifically about attribute information. For example, you want to see immediately in the system what that want now say attribute base colour. When you ask a temporary worker to do data management, they should be able to easily know what data complements each attribute. We call this attribute metadata: what specifically needs to be completed per attribute? Within your ERP, ‘basic colour’ is going to be there, but no further information. Within PIM, however, you can store this. You can add not only a description of the attribute, but also who is responsible and where the attribute is distributed to (e.g. towards ETIM or marketplaces). Within PIM, this metadata is also easy to manage and modify.

Can PIM and ERP work together?

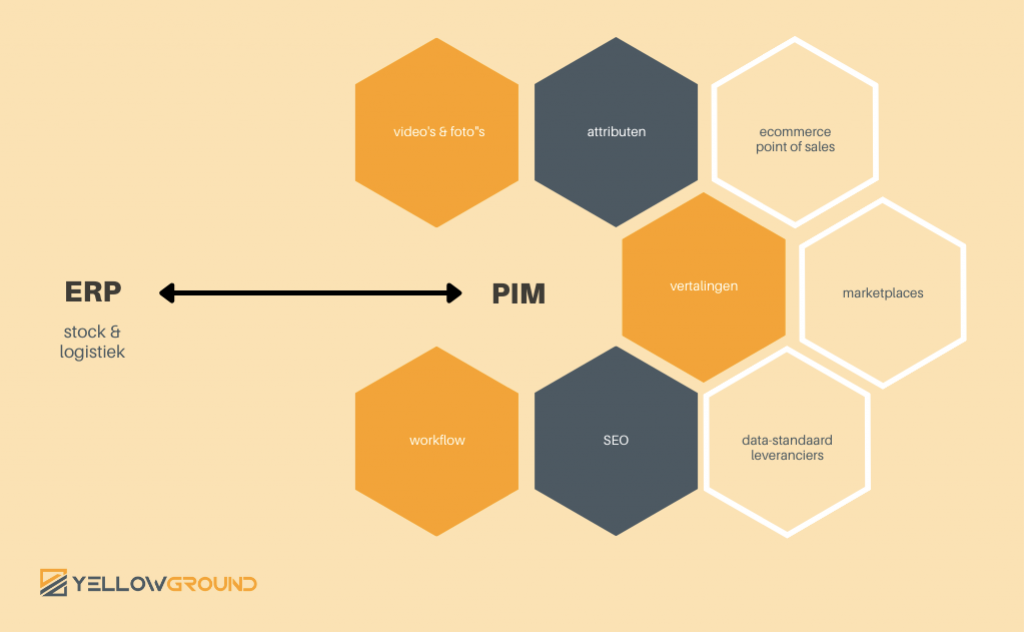

Yes indeed! ERP and PIM systems can work together in perfect harmony. ERP systems include numerous information points about a company, such as logistics, products, customers, stock availability, location of warehouses, and prices. They are built to keep track of stocks of products, their movement within the organisation until they are sold. An ERP has a very different way of looking at products, namely in a commoditised way, looking at marketing and sales in a superficial way. Marketing, on the other hand, constantly looks for vivid product descriptions and imagery to make products attractive. It is exactly this void that PIM fills. A PIM system takes product information from an ERP system (and several other systems) and enriches it to make it suitable for marketing and sales.

Business case by business case, one has to look at which questions ERP provides an answer to and for which questions PIM provides a solution. A well-implemented PIM system provides the consistent data quality that is indispensable for your demanding customers in an omni-channel experience.